One of the first things they teach you in Writing Skool is Every Story Is A People Story.

It sounds far-fetched, but it has proven to be true. This month’s blog post is about some of the wonderful people I met during the development of the original 1965 Mustang Independent Rear Suspension (I. R. S.) and how those people relate to the Mustang as we know it today.

I started that quest over 40 years ago when I connected with the German-born engineer, Klaus Arning, who was head of Ford Advanced Suspension Design in 1965.

Klaus and I became good friends. He visited my shop in Utah and we attended several SEMA shows together before he passed in 2000. I lost track of the Arning name, but I knew Klaus had 3 sons, all of whom had worked for Ford at some time.

SEMA sponsored an escorted tour of the Big Three (Ford, GM, and Chrysler) in 2005 . The Ford portion visited the Flat Rock, MI, plant where the Mustang is made, and I couldn’t pass up this once-in-a-lifetime opportunity. As I checked into the historic Dearborn Inn, originally built as the airport terminal for the new Ford Tri-Motor aircraft, from over the front desk a portrait of old Henry looked down at me. I thought, wouldn’t it be cool if I ran into one of Klaus’ sons during this tour. Yeah sure, of all the thousands of employees at all the Ford plants, the odds ain’t great.

The next morning, as scores of fellow gear heads assembled in the Flat Rock lunchroom, our tour director stood up and said, “Welcome to Flat Rock. My name is Ralph Arning and I’ll be leading your tour this morning.” Coulda knocked me over with a feather.

After the tour, I introduced myself to Ralph, and he said, “I had a completely irrational feeling that you might be here today.” We met at the Dearborn Inn for dinner that evening, and I swear old Henry was smiling at us. We were in “limited production” of the I.R.S. I had chucked a hub carrier into my luggage in case someone was interested in buying an I.R.S. and Ralph was thrilled to hold one of his father’s designs in his hands. To this day, when I hear the term serendipity I think of that night.

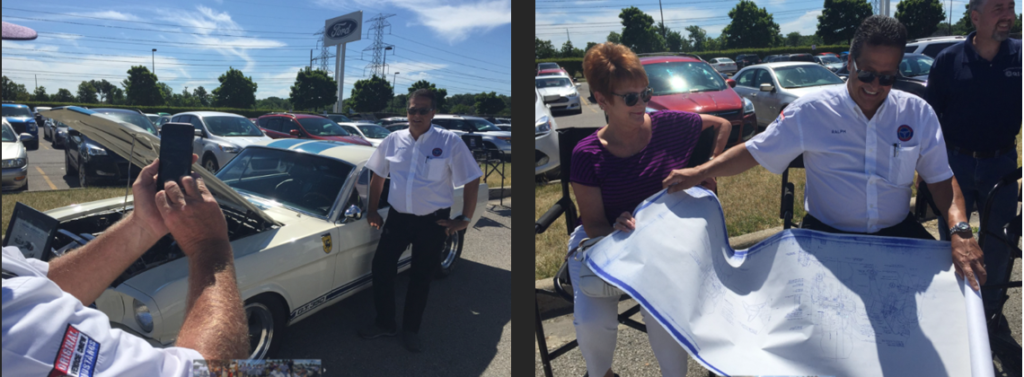

About this time, Jim Marietta, Ted Sutton, and Peter Brock put together the Original Venice Crew (O.V.C.). We built two Mustangs, one with an I.R.S. at Peter’s shop “The way we would have done it if time and money didn’t get in the way.” Our first test run was at Willow Springs on the 50th anniversary of the first GT 350 win, and Ralph was able to attend and meet the whole crew. Randy Richardson, along with Mike Eisenburg, are pictured pointing out the finer points of Klaus’ creation.

Following that, we did a Back To The Beginnings Tour, and hit all the vintage races and shows we could string together during a 30 day road trip. A stop at Flat Rock, the Henry Ford Museum, and the “Glass House” executive offices occupied several days. The contacts we made were priceless. Everyone was gracious and made time for us in their schedule. A later visit resulted in some marketing agreements.

The cars and the O.V.C. team have been invited to more shows and races than I can remember. One of my favorites was the lawn at Pebble Beach the year they honored the GT-40.

Klaus was instrumental in designing the suspension system that helped beat Ferrari. Ford and Lincoln were the honored marques, and Edsel Ford II and Henry Ford III both came by to say hello.

Perhaps my all-time favorite was at Laguna Seca, now renamed Weather Tech Raceway, when Jim Owens asked us to put the cars that we built in Peter’s shop on the front row for a poster shot of the vintage races.

Jim is Shelby and Mustang Brand Manager at Ford, and one of the people who decide who is allowed to purchase a new MUSTANG GTD (almost 8,000 have applied). You have to be someone special to buy the 800+ H. P., 200+ MPH, carbon fiber/aluminum/titanium monster. Prices start around 300K and go up from there, depending on options. You will want the titanium exhaust option at about 2.5 K. It sounds great and saves almost 2.5 pounds! At least 1,000 GTDs will be made to meet homologation requirements. The GTD’s purpose in life is to beat the Porsche GT2 RS and the GT3 RS around Germany’s Nurnbergring. Mustang outsells Porsche in Europe, with equal or better performance at half the price.

Ford C.E.O. Jim Farley keeps a MUSTANG GTD along with a vintage 427 Cobra at his garage/shop/apartment condo above pit row at Weather Tech. Jim, if you’re reading this, I’m available to keep your condo clean, your refrigerator stocked, and see that your cars get plenty of exercise.

In 2013-4, National Geographic’s ULTIMATE FACTORY series decided they wanted to do a show about automobile factories. They contacted Ford at Flat Rock, as Flat Rock is one of the few factories in the world that takes all the raw materials and forms them into a driveable car on site. To put the show together, they needed someone who could interface between the Ford production line workers and the Nat. Geo. film crew, knew the technical side inside and out, and could put together a tour that made all of the pieces come together. The only person that fit that description was the now 7-years-retired Ralph Arning, living at his retirement home/shop in St. George, Utah. Welcome back Ralph! Filming took about a month.

Every story really is a people story, isn’t it? In this case, some really remarkable people.

Thanks for listening.

Duane

Best part is that it’s mostly true!

Duane didn’t mention that he helped me move into my new home in Utah!

True friend!

I’ve shared many conversations with gentlemen in our over-55 community who fancy themselves as “Mustang afficionados”. The moment I mention an IRS setup for the car, they’re all ears. Few—if any—were even aware of its existence. I’m happy to mention your involvement and the fact that we’re related. Your story is a remarkable series of events; perhaps Herr Klaus is silently guiding things along to ensure his legacy.