In 1967, my best buddy and I went to see the hit movie The Graduate, where Dustin Hoffman’s character is advised that the future is “PLASTICS!” I graduated college in 1969, and a division of Borg Warner Corp. called Marbon was advertising they had built The All Plastic Car out of a material known as ABS (Acrylonitrile Butadiene Styrene), tradenamed Cycolac. That sounded interesting, since I loved cars and wanted to embrace the future.

I sent Marbon a letter, along with a glowing recommendation from the BYU faculty, and after a couple of phone interviews they mailed me a plane ticket to Parkersburg, West Virginia. A week of interviews, including two days at Psychological Services in Pittsburg, resulted in a job offer as their #3 Industrial Designer. Wahoo!

That era was known as “The Go-Go Years.” (Remember Go-Go Boots and Whiskey a Go-Go?) Formerly staid companies were making wild bets with easy money and easy credit. Cycolac ABS was being used in everything from NFL football helmets to kitchen appliances to automobile parts. Deacon Jones, a 6-5, 270 lb. defensive end with the L. A. Rams was our spokesperson, and every Cycolac ad ended with the tag line “Deacon Does.”

My boss was a big Scandinavian named John Helgesen, and my frequent traveling companion from the Ad Dept. was a fun-loving Irishman named Chuck Harley. Together we covered the USA and most of Canada. There was nothing we wouldn’t tackle!

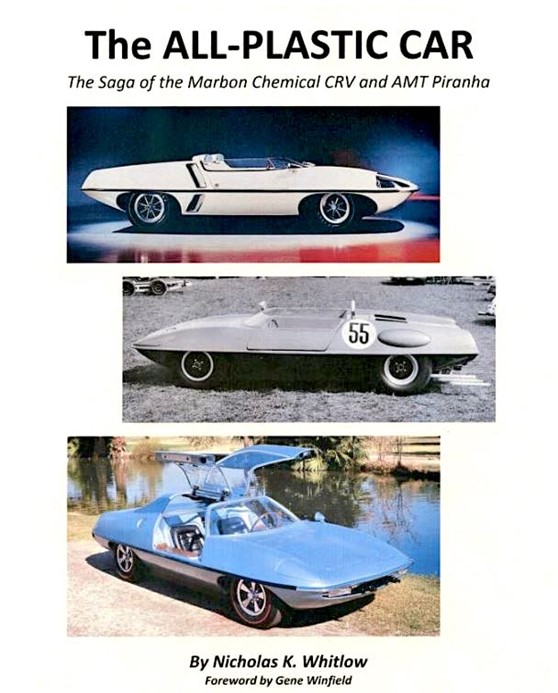

Borg Warner is a well-established (1928) automotive corporation, and we did lots of business with The Big Three in Detroit. Knobs, switches, chrome-plated grilles (replacing heavy, costly, die-cast grilles) made up a large share of our business. Somebody in management decided “If a little’s good a lots gotta be better. Let’s make the whole car outta plastic!” It was called the Cycolac Research Vehicle (CRV) and they touted it as the wave of the future.

(loved the short skirts & the tall hair)

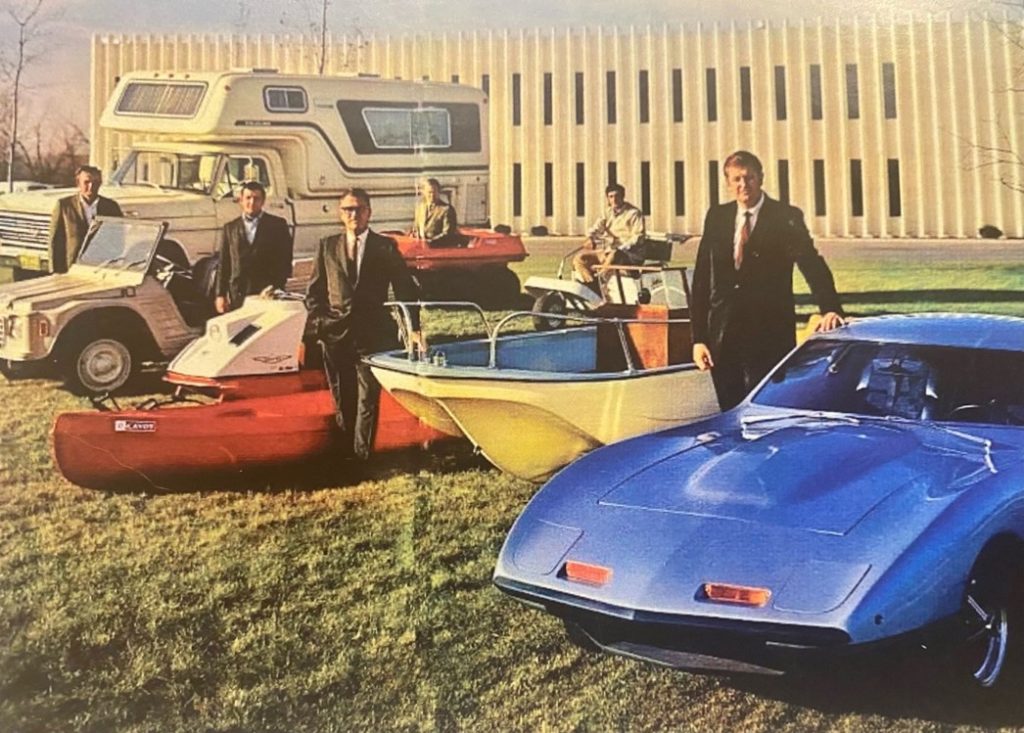

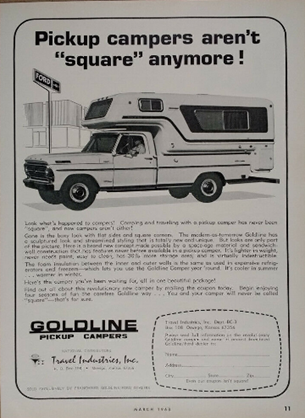

We made or helped our customers make not only car bodies, but boats, canoes, ATVs, and my favorite, the Goldline Camper. We designed it, our customer produced it, and it was sold exclusively through Ford dealers. Instead of plastic parts weighing ounces, we were going to sell parts weighing tens or even hundreds of pounds. Management was ecstatic!

The Goldline was colorful, aerodynamic, lightweight, and well-insulated. Made of four pieces, left & right exterior pieces glued together down the centerline, and left & right interior pieces made the same way, with urethane foam injected in the void between the inner & the outer. Chevy and Dodge dealers were supposedly green with envy, as they offered their square, stick built, heavy aluminum skinned campers that squeaked, rattled and leaked air & water. We were heroes, geniuses, and good looking too. Even Deacon said so.

About here is where we “shudda knowd better.” There is a thing called “co-efficient of linear thermal expansion,” or CTE, which affects all solid materials. Wood doesn’t expand much, metals expand some, but most plastics expand and contract a lot. For ABS plastics, the CTE is about 6 hundred thousands (.00006”) of an inch/per inch/per degree. Doesn’t sound like much does it? Everyone knew it was there, but no one thought to do the numbers. Let’s do them some 50 years later.

Up one side of the camper, roughly 9 feet, across the top, roughly 8 feet, down the other side, another 9 feet, and now across the bottom another 8 feet. That’s about 34 feet. Stay with me here! 34 feet X 12 inches gives you 408 inches.

You are ice fishing in Northern Minnesota and it’s -40 outside. Add the number of degrees outside to the temperature inside your camper (+75) which is held at room temperature by the built-in propane heater. That’s 115 degrees difference (+75 degs. to -40 degs).

Now times that by the inconsequential .00006 inches.

408 x 115 x .00006 = 2.82

That’s almost three inches! Not too bad unless the frigid outside is glued tightly to the toasty inside by the urethane foam filler. That difference has gotta be accounted for somehow!

The story we all heard was, “Me and my three buddies were ice fishing all day, and at night we were in my Goldline smoking cigars, drinking whiskey and playing cards in our boxer shorts. Loved that camper, it was warm and toasty. All of a sudden, I heard what sounded like a shotgun blast and a big split appeared in the roof. I could see stars outside. A blast of -40 degree air hit me right in the crotch.” Oww!!

Yeah, well, we shudda knowd better, but we were having too much fun.

There was a new predator in the corporate jungle called Consumer Advocate, and a guy named Ralph Nader had just taken GM to the cleaners for their “unsafe” Corvair. Marbon and Ford couldn’t shut down Goldline fast enough, and all the sold units were recalled. Too bad. It was a good design. No! It was a great design, if you didn’t take it to northern Minnesota in the damn winter in your damn boxer shorts.

I was in the meeting when one of our most senior executives said, “Well, maybe we don’t have the material for big structural parts.” Cautious murmurs of agreement came from less-senior personnel all around the table.

We shut down the Large Structures Lab, and the CRV car business was sold to AMT, makers of plastic car models. They made a few, but eventually the CRV vanished into that land of “good idea ..but.”

We went back to helping people design all manner of parts. ABS and its plastic cousins can be molded and textured or plated to look like just about anything.

As I sit in the cab of my new Ford truck, thinking about Marbon some 50 years ago, the handsome dashboard appears to be top grain hand-stitched leather, the heat vents are bright chrome, the center stack is polished black walnut surrounded by brushed aluminum, while the steering wheel is a combination of blond oak and hand sewn glove leather. In the center of the wheel is a sterling silver oval with the Ford logo rendered in rich blue lacquer.

All very nice, but I know who you guys REALLY ARE! Every one of you is plastic, disguised as something else and doing it better than the real article ever could.

Dustin Hoffman would be proud. Plastics done in the right way really are the future, and the present. The average new car now contains over 350 lbs. of plastic, up from about 10 in Dustin’s day. I enjoy watching them become better, more cost effective, and now even more recyclable. R.I.P. CRV.

Thanks for listening.

Ps. Order The All Plastic Car By Nicholas Whitlow from Amazon. It’s a good read.